Stainless steel 316 is a well-known alloy and one of the most commonly used materials for fasteners. Despite its widespread application across various industries, 316 stainless steel can sometimes fall short when it comes to handling demanding applications that require high strength, temperature resistance, and corrosion protection. Let’s take a closer look at how it compares to some other specialized stainless steel alloys in these key areas.

### Strength

When it comes to sheer strength, 316 stainless steel doesn't stack up as well compared to many specialty alloys. While it offers moderate strength options similar to duplex steel, extreme steel alloys like A286 and 17-4PH bolts can achieve an ultimate tensile strength of up to 210 ksi—nearly three times stronger than a standard 316 bolt. If you're working in an environment that demands superior strength, these alternatives might be worth considering.

### High Temperature

316 stainless steel bolts can operate effectively from sub-zero temperatures up to around 800°F. Beyond this point, the material's mechanical properties degrade, and oxidation becomes more likely. This places 316 in the middle of the temperature spectrum for stainless steel. Some specialty stainless steels, like duplex steels and 17-4PH, also experience changes in their characteristics above 570°F or 600°F. However, certain heat-resistant stainless alloys such as A286, alloy 310, and alloy 330 are specifically designed to withstand temperatures up to 2100°F while maintaining stability and resisting oxidation.

### Corrosion

Although 316 stainless steel isn't as corrosion-resistant as nickel alloys, it performs adequately in mildly corrosive environments. It's often used to resist sulfur compounds, acetic acid, and phosphoric acid. On the other hand, Alloy 20 is a stainless steel alloy explicitly designed for enhanced corrosion resistance, offering superior protection against acids like hydrochloric acid, sulfuric acid, and nitric acid.

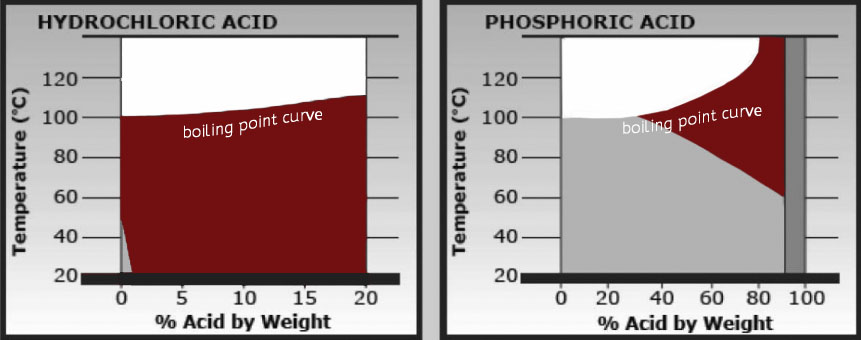

The chart below illustrates the corrosion behavior of 316 stainless steel in different acidic environments:

For marine environments, AL6XN (also known as 6 Moly Alloy) is a better choice due to its superior saltwater corrosion resistance compared to 316 bolts. Similarly, duplex and super duplex stainless steel bolts outperform 316 in chloride and mild saltwater corrosion scenarios. Depending on your specific corrosion needs, alloys like Alloy 20, AL6XN, and duplex steels could provide better performance than 316 stainless steel.

### Chloride Stress Corrosion Cracking

In chloride-rich environments, 316 stainless steel can suffer from chloride stress corrosion cracking, whereas duplex 2205 stainless steel shows much greater resilience. The following chart highlights this difference:

As always, selecting the right stainless steel depends on the specific conditions of your application. For example, if you're dealing with harsh marine conditions, alloys like Alloy 20, AL6XN, and duplex steels are typically better choices than 316 stainless steel.

In summary, while 316 stainless steel remains a versatile and popular option, it may not always meet the demands of highly specialized applications. Specialty alloys like A286, alloy 330, and duplex steels offer enhanced strength, temperature resistance, and corrosion protection, making them ideal for more challenging environments. Always consider the exact requirements of your project before deciding on the appropriate material.

Rectangular Return Air Duct,Heat Insulation Air Duct Systems,Duct Air Conditioners,Air Conditioning Ducts

Jiangsu Buna Technology Development Co. , Ltd. , https://www.bunaduct.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)