Silicone sealant is a type of sealing material that belongs to the same system as common glass glue. It is typically composed of materials like sodium silicate and silicone-based structural polymers. The acetic acid type, such as methyl triacetoxysilane, ethyl triacetoxy silane, and vinyl triacetoxy silane with organotin catalysts, offers good adhesion to most materials, produces transparent results, and provides moderate mechanical strength. However, it can be corrosive to metals and cures quickly on the surface.

The deacetylated version, including methyl triacetone silane and methyl tributol oxime silane with organotin, is odorless, neutral, and generally non-corrosive. It has good oil resistance but tends to have lower mechanical strength and adhesion. It may also be corrosive to copper.

The dealcoholic type, such as methyl trimethoxysilane, ethyl triethoxysilane, and vinyl trimethoxysilane, along with Nanda-42 and Nanda-73 organotin, and titanate chelates, is odorless, non-corrosive, and offers slow surface curing, strong adhesion, and high strength. However, its storage life is short (4–6 months), and it must be stored at low temperatures. Reactivity is generally low, except for Nanda.

Deaminized monomethyltricyclohexylaminosilane exhibits good adhesion to concrete and limestone building materials but is corrosive to metals and has low strength, limiting its use in many applications.

Deamidated compounds like CH3Si[N(CH3)-C(=O)-CH3]3 and (CH3)2Si[N(CH3)-C(=O)-CH3]2 offer high elongation and long-lasting flexibility but have low modulus and weak tensile strength for sealing applications.

Deketalized CH3Si[OC(=CH2)-CH3]3 and methyltris(isopropenyloxy)silane Si[OC(=CH2)-CH3]4 are less commonly used due to their limited properties and specialized applications.

Tetrakis(isopropenyloxy)silane with titanate and organic amine is odorless, non-corrosive, non-toxic, and provides excellent adhesion and stable storage. However, its synthesis process is complex and costly.

Silicone sealant is widely used in various construction and industrial applications:

1. Ideal for sealing joints in aluminum alloy, titanium alloy, and plastic steel doors and windows during installation.

2. Suitable for weatherproof sealing in glass curtain walls, aluminum-plastic panel curtain walls, and stone dry hanging systems.

3. Used for sealing sash doors and windows, ensuring durability and airtightness.

4. Perfect for bonding porous stone, laminated glass, insulating glass, mirror glass, coated glass, and metal surfaces like zinc, copper, and iron.

5. Appropriate for sealing joints between different materials such as glass, metal, aluminum, ceramic tiles, plexiglass, and coated glass.

6. Effective for sealing joints on concrete, cement, masonry, rock, marble, steel, wood, anodized aluminum, and painted aluminum surfaces—often without the need for a primer.

7. Suitable for bonding ceramics, sanitary ware, marble, and other materials on dry surfaces, including glass, most grease-free wood, silicone resins, sulfurized silicone rubber, ceramics, natural and synthetic fibers, and various plastics.

8. Can be used to bond ceramics, sanitary ware, marble, and similar materials for long-lasting performance.

For more detailed information about our products or to discuss your specific needs, please contact Hebei Xingda Insulating Glass Aluminum Strip Factory. Contact number: 15731674467. Contact person: Business Manager.

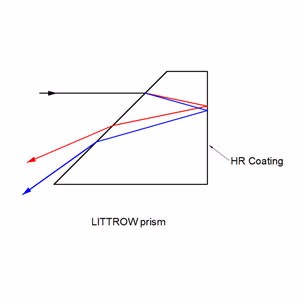

Littrow prisms feature 30°, 60°, and 90° angles .30° - 60° - 90° Littrow Dispersion Prisms can be used for a variety of applications. Uncoated littrow dipersion prisms are used to disperse light into its component spectrum. Coated littrow dipersion prisms are used to deviate the line of sight by 60°.

Dispersion Prisms (Uncoated)

Collimated white light enters into the A-C surface of the prism, is reflected at the hypotenuse surface, and then dispersed into its component spectrum at the B-C surface. Although Littrow prisms produce narrower dispersion than equilateral prisms, Littrow prisms are typically less expensive.

Beam Deviation Prisms (Coated)

Incident light enters into the aluminum coated B-C surface of the prism at the nominal angle and returns back using the same path. In spectrum dispersion applications utilizing white light, the resolution performance of Littrow prisms is equal to equilateral prisms since the optical path length through the glass substrate is the same distance round-trip. Additionally, light entered into the A-C surface will reflect twice inside the glass substrate before being emitted through the hypotenuse surface at 60°.

Â

Dispersion Prism,Optical Dispersion Prisms,Beam Deviation Prisms,Inked Dispersion Prism

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)