# Understanding Orlock® Rivets and Magna-Lok® Rivets

When deciding between an Orlock® rivet and a Magna-Lok® rivet, many customers wonder about their differences and which might be the better choice. Both rivets are popular options in the structural rivet market, each offering unique advantages depending on the application. In this article, we’ll explore the key features, benefits, and applications of both rivets to help you make an informed decision.

---

## What Makes Orlock® Rivets Special?

Orlock® rivets are renowned for their robust double-locking mechanism, which secures the materials on both sides of the panel. This design ensures excellent vibration and weather resistance, making them ideal for demanding environments. The rivets feature a compact, non-protruding blind side bulb, which helps distribute the load effectively while preventing pull-through.

One of the standout characteristics of Orlock® rivets is their ability to work efficiently within a limited material grip range. This makes them a practical choice for applications where space is constrained. They can be easily installed using a Huck gun or any compatible structural rivet tool, ensuring quick and reliable assembly. Known also as Allok® or Hemlok® rivets, these products are widely trusted across industries for their durability and performance.

---

## The Versatility of Magna-Lok® Rivets

On the other hand, Magna-Lok® rivets stand out due to their flexibility in handling varying material depths. With a broader material grip range, they provide greater adaptability than many other standard structural rivets. This versatility translates into significant cost and time savings, especially when dealing with projects that involve multiple grip variations.

Another key advantage of Magna-Lok® rivets is their flush pin break, which leaves a smooth and even surface after installation—eliminating the need for grinding or filling. This feature enhances the aesthetic appeal of your final product while maintaining its structural integrity. The unique solid-circle lock design ensures maximum strength and resistance to vibration, making these rivets particularly suitable for heavy-duty applications.

---

## How Do Structural Rivets Work?

Unlike standard rivets, structural rivets incorporate an internal mechanism that locks part of the pin (mandrel) inside the rivet body. This design strengthens the joint and provides better material retention. Depending on the type, structural rivets either broaden the body or compress it to create a bulb on the blind side.

For instance:

- **Magna-Lok® Rivets**: Expand the body to widen against the material.

- **Orlock® Rivets**: Compress and bulge the body to form a bulb against the material.

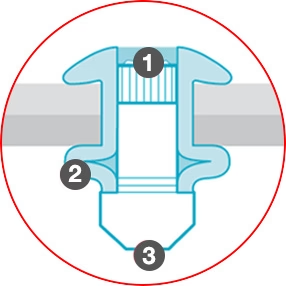

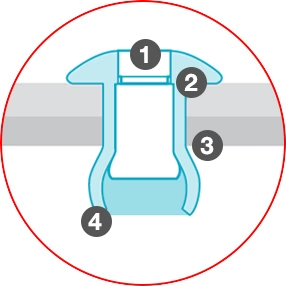

To better understand the blind-side formation, refer to the diagrams below:

### Orlock® Structural Rivet

- Positive mechanical pin retention ensures structural integrity.

- A band-annealed bulging system provides superior blind-side strength.

- The tapered hole-seeking tip facilitates quick and easy installation.

### Magna-Lok® Structural Rivet

- Flush pin break leaves a clean, even surface without grinding.

- A unique solid-circle lock maximizes strength and vibration resistance.

- Excellent gap pull-out capability and high retained clamp.

- The sleeve expands during installation to create a moisture-resistant joint.

---

## Which Is Stronger: Magna-Lok® or Orlock®?

The answer depends on whether you prioritize tensile or shear strength.

- **Magna-Lok®**: Offers higher tensile strength, meaning it can handle more stretching stress before failing.

- **Orlock®**: Has a higher shear strength, making it ideal for applications requiring resistance to sliding forces.

Below are the lab test results for both rivets:

| **Rivet Type** | **Shear Strength (kN)** | **Tensile Strength (kN)** | **Grip Range (mm)** |

|----------------|-------------------------|---------------------------|---------------------|

| Magna-Lok® | 5.7 | 4.4 | 1.6–11.1 |

| Orlock® | 5.9 | 3.5 | 3.5–6.0 |

---

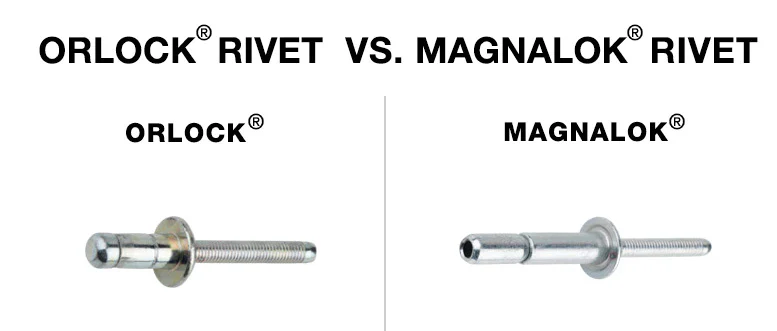

## Identifying the Difference Between Orlock® and Magna-Lok®

To avoid confusion, always check the physical characteristics of the rivets. Below is a comparison image:

Be cautious when purchasing, as unscrupulous suppliers may pass off counterfeit rivets under legitimate brand names. Always verify authenticity to ensure quality and reliability.

---

## Conclusion

Both Orlock® and Magna-Lok® rivets excel in different areas, making them valuable tools for various industrial applications. While Magna-Lok® offers superior flexibility in material grip, Orlock® provides exceptional shear strength and compactness. Choosing the right rivet ultimately depends on the specific requirements of your project.

If you need help selecting the best structural rivet for your needs, feel free to contact us at 02 9755 3747 or reach out via our website.

At Aerobolt Australia, we pride ourselves on being the leading distributor of genuine Huck bolts and structural rivets. Our commitment extends beyond sales—we also offer expert service, tool hire, and maintenance solutions to ensure you get the most out of your equipment.

**Copyright © 2024 Aerobolt Australia Pty Ltd. All rights reserved.**

Ce Emergency Exit Sign,Illuminated Exit Signs,Fire Safety Signs,Exit Sign With Emergency Lights

JIALINGHANG ELECTRONIC CO.,LTD. , https://www.jlhemergencylighting.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)